How to quickly evaluate the long-term stability of the cosmetic product?

To reach the point of sale, the cosmetic product can travel for miles, even by air or by ship, undergoing prolonged mechanical and thermal stress.

Additionally, how many times in the summer do you leave your sunscreen in the sun or forget a cosmetic product in the car? The high temperatures that are reached could have an impact on the physical stability of the product and significantly modify its functional and application characteristics.

These are just some of the possible causes of altering the stability of a product from the moment it leaves the production factory to when it is used by the consumer. The stability over time of a cosmetic formulation is a mandatory requirement to guarantee the quality and safety of the product. It is therefore essential that the structure of the product does not change irreversibly over time and with variations in temperature. For this purpose, during the research and development phases of a cosmetic product, the formulator must ensure high quality standards and an adequate shelf-life.

Conventional methods for studying the stability of cosmetic emulsions, such as the accelerated aging test, conducted by placing the product in special thermostated chambers, are necessary but time-consuming and allow only evident organoleptic changes to be observed.

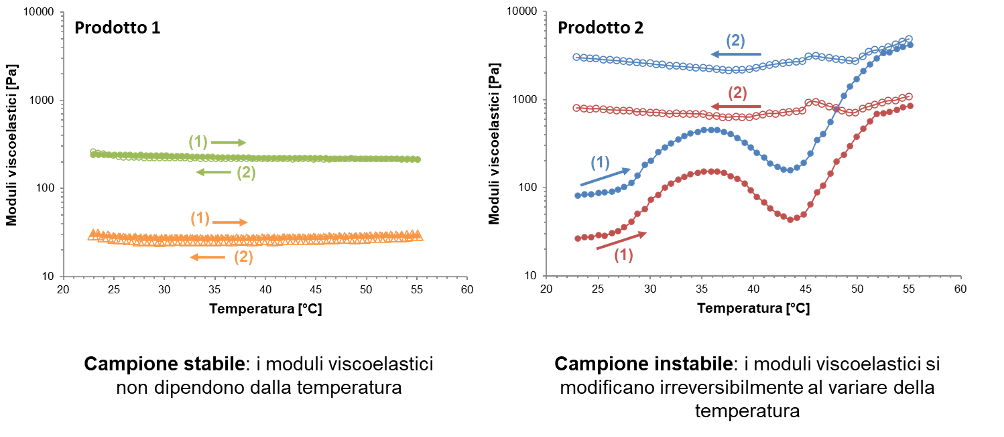

To measure, in a short time and in an objective and reproducible way, the dependence of the formula on thermal stress and to evaluate if it is suitable to guarantee the stability required in its use, rheological measurements of Temperature sweeps are carried out in our laboratories. These are analyses conducted in conditions of oscillatory motion, which allow monitoring the changes that occur in the internal structure of the sample as a function of the temperature, which is made to vary by applying a heating or cooling ramp.

This approach is able to reduce product development times, because it allows to predict, in a simple and fast way, the criticalities that may occur over time or that may be encountered during the production, transport and storage of products. A gradual increase in temperature, in fact, allows to speed up the kinetics of the phenomena that can lead to internal instability.

For further information, please contact us at +39 334 6812046 or by email at info@unired.it